Bending titanium can be done in various ways such as cold working and heating among other methods. Titanium is said to have low modulus of elasticity which makes it easy to manipulate by shaping and bending it. It can return back to its original shape even after bending it. This is what is termed as a memory alloy.

Titanium is bent with equipment known as a titanium tube bender. Titanium is not magnetic, nor is it biocompatible. This means that it is non-allergenic and non-toxic and for this reason, it is majorly used in the medical field.

Characteristics of Titanium that Make it Bendable

There are six main distinguishing factors of alloy that make it easy to bend when compared to other metals. These characteristics are what make it easy to fabricate and manipulate.

- Titanium is low in density

- It contains a lower modulus of elasticity

- It has low ductility

- It has a proper propensity to gall

- Its melting point is higher

Titanium has a higher sensitivity in regards to contamination during the welding process

Things to Consider when Bending Titanium

There are various things you need to keep in mind when bending titanium because a lot goes into it.

1. The State of Your Work Area

The workspace that you use when working with titanium needs to be as clean as possible. Eliminate any traces of dust, moisture, grease or contaminants that may tamper with the metal. If possible, ensure that you isolate the work area from the rest of the space.

2. Identify Your Forming Technique

While forming titanium using equipment and technique used for steel, you can comfortably do it at room temperature. Ensure that you have the correct parameters before you proceed.

The formation of titanium is realized by several factors; titanium has room temperature ductility. However, when you need to bend it severely, you require hot forming.

The modulus elasticity of titanium is usually half that of steel metal which gives titanium a good allowance to spring back to its original shape/form.

3. Preparation Criteria for Forming

Sharp edges and burred surfaces are should be filed smooth before you begin forming to prevent its edges from cracking. During handling, you may be required remove some surface marks and gouges by sanding it or picking those areas.

Ways on How to Bend Titanium

There are various criteria on how to bend titanium metal. They are such as: cold forming, springback, hot forming, drawing and so on and so forth.

1. Cold Forming

When cold forming titanium, the settings must always be on slow speed. The room temperature formation criteria for titanium is far much different than that of cold forming because of the different tensile capabilities.

2. Hot Forming

As you increase temperature, the bendability and stretching capabilities of titanium increase. Therefore when hot forming, you should elevate the temperature to one that is above the room temperature. In essence, the higher the forming temperatures, the easier it will be for you to form the titanium.

Oxidation of surfaces for titanium are possible at temperatures above 1100 degrees Farenheit. You can use a furnace, direct flame impingement or a radiant heater as your sources of heat.

3. Springback

When forming or bending titanium, ensure you leave and allowance of about 15 to 25 degrees since the metal will have a spring back effect. The degree of the springback is dependent on the strength of the alloy. To compensate for the springback, you will need to over form it. When hot sizing cold formed titanium and any of its alloys, you will eliminate the springback therefore giving an allowance for stress relief.

4. Drawing

Titanium has the tendency to gall, therefore when drawing, you have to take extra caution. The surface of titanium being drawn may fail as a result of galling. Galling can also mar the surface of the metal. Lubricate the titanium properly to prevent it from having direct contact with the dies and tools in use.

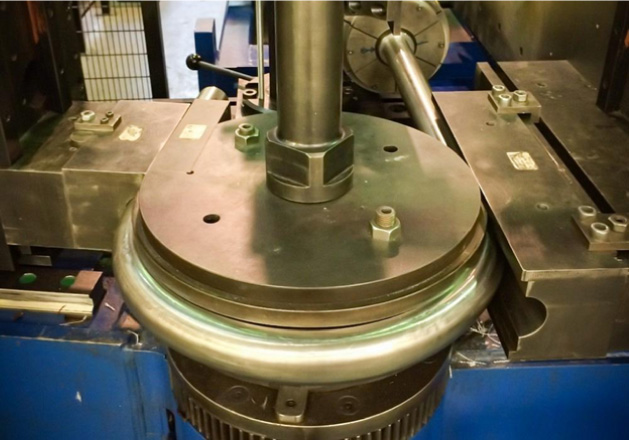

5. Tube Bending

This form of titanium bending is done with the use of equipment suitable for conventional tube bending. For tight bends, it is recommended to use mandrel benders. Not that, any form of bending should be done slowly to prevent galling. Temperatures required for titanium tube bending are about 400-600 degrees Fahrenheit.

6. Roller Expansion

This method is used in turning titanium tubes into sheets. The most commonly used method of making tube/tube sheet joints is roller expansion. Ensure that the tube sheet holes are made within the limits specified by TEMA (Tubular Exchanger Manufacturers Association). As for shell and tube heat exchangers they should remain within the limits specified by HEI (Heat Exchange Institute) Standards for Steam Surface Condensers.

7. Interference Fit Method

For this bending method, there are four measurements that you should always put into consideration.; the tube wall thickness, tube ID, the sheet hole diameter and the tube O.D. It is not advisable to use this titanium bending method because it presumes that the tube is perfectly round. The method is also dependent on the inability of the tube sheet to be enlarged.