There are several factors that determine the CNC machining cost. The point of understanding these factors is so that you can improve on the service of the machines and produce products that are high quality. Therefore, before weighing your industry’s machining costs, you need to have the following in mind:

1. The Material in Use

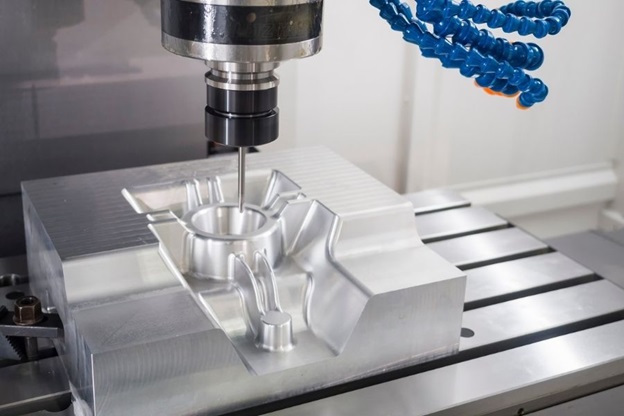

The material in use is very substantial when it comes to CNC machining costs. So what is CNC machining and how does it work? The subtractive process of CNC machining often tends to utilize more material than the material which will make the end product.

There are two materials that are utilized when weighing out the cost of machining. These are metals and plastics.

Metals:

The one that is most commonly used is Aluminum 6061 for the sole reason that it is economical and it is well compatible with most machines. The other metal commonly used is the Stainless 303 which offers a good amount of machine compatibility. The other commonly used metal is Brass C360.

Plastics:

These are much cheaper to use compared to metals since they require a shorter duration for machining (mostly since they contain lower hardness). The common plastics used are such as POM, Nylon 6 as well as ABS. These types of plastics also contain a similar bulk cost to that of metals such as Aluminum 6061. However, PEEK, which is a type of plastic, can be quite expensive, especially if you weigh it in terms of bulk costs.

2. Cost of Machining

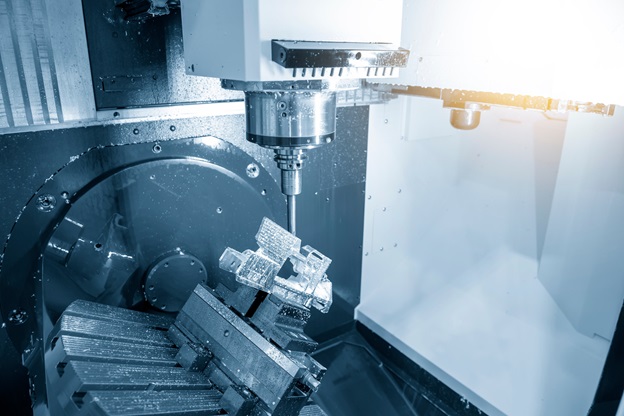

The cost of machining is solely dependent on the type of machine you are using. There are two types of machines that are usually used. They are such as the 3-axis machine and the Multi-axis machine.

Multi-axis machines are a little costly compared to 3-axis machines. The cost of machining is also dependent on other factors. The buying price of the machine and the number of hours your machine will be actively running annually. The market price of the machines is calculated by dividing the price of the machine and the number of hours the machine will be running.

3. Labor Costs

CNC machining is majorly done by automation and not manual laboring. Therefore, you do not require a lot of employees. So the labor costs to put into consideration here are based on the digitization process and the design creation processes. In CNC machining, labor costs are in three categories:

Programming Costs

The most expensive of the three labor costs since it is the force behind digitization, design creation processes, and programming processes. Ideally, you would be required to outsource a product and create a unique design for it. The alternative would be for you to come up with a unique design. Either way, you will incur some costs.

Set-up Costs

Machine operator cost is inclusive of the set-up costs. A machine operator is a person in charge of setting up the CNC machines to ensure maximum optimization of the machine. The setup of the machine is usually dependent on the amount of bulk being produced.

Post Processing Costs

Transportation and assembly are some of the post-production activities that are carried out in industry. These processes require manual labor, which adds to the CNC machining costs.

4. Other Additional Costs

There are some extra costs that are usually incurred during the CNC machining process. They consist of:

Tooling Costs

The industry will more often than not be required to purchase some additional tools to aid in the production process. The tools may be used for various purposes but the costs for some of those tools may be incurred, especially if the tools are subjected to wear and tear during the production processes.

Surface Finishing Costs

The appearance of the CNC machined parts is commonly improved by surface finishing. These costs may be overlooked but they are important to consider since at the end of the day, you will be required to cater to them.

Tips on How to Reduce CNC Machining Cost

All the factors considered on what it takes to calculate the CNC machining costs, there are several tips on how you can be able to reduce those costs. These tips should help your industry produce more while incurring fewer costs.

1. Consider the Material in Use

Before employing a material in your production processes, first weigh the pros and cons, as well as its price. Different materials require different machining times and they all contain different machinability. These factors ultimately determine the hourly rates for your CNC machine shop. That is why the material in use is an important aspect to consider.

2. Design Optimization

The design template for your industry’s manufacturing processes is also quite critical when it comes to calculating the CNC machining costs. The more complex the design you choose, the longer your machining time and the higher the costs you will have to incur to produce the end product.

3. Outsourcing

You can minimize your CNC machining costs by outsourcing some elements used in the machining processes. An example of a country where you can outsource your tool at higher quality and a cheaper price in China.

In Conclusion

The above factors and tips should enable you to calculate the CNC machining costs and help you arrive at the most efficient and applicable CNC machine.