Pharma companies are using every tool in the digital transformation toolbox to make and deliver billions of doses safely and quickly.

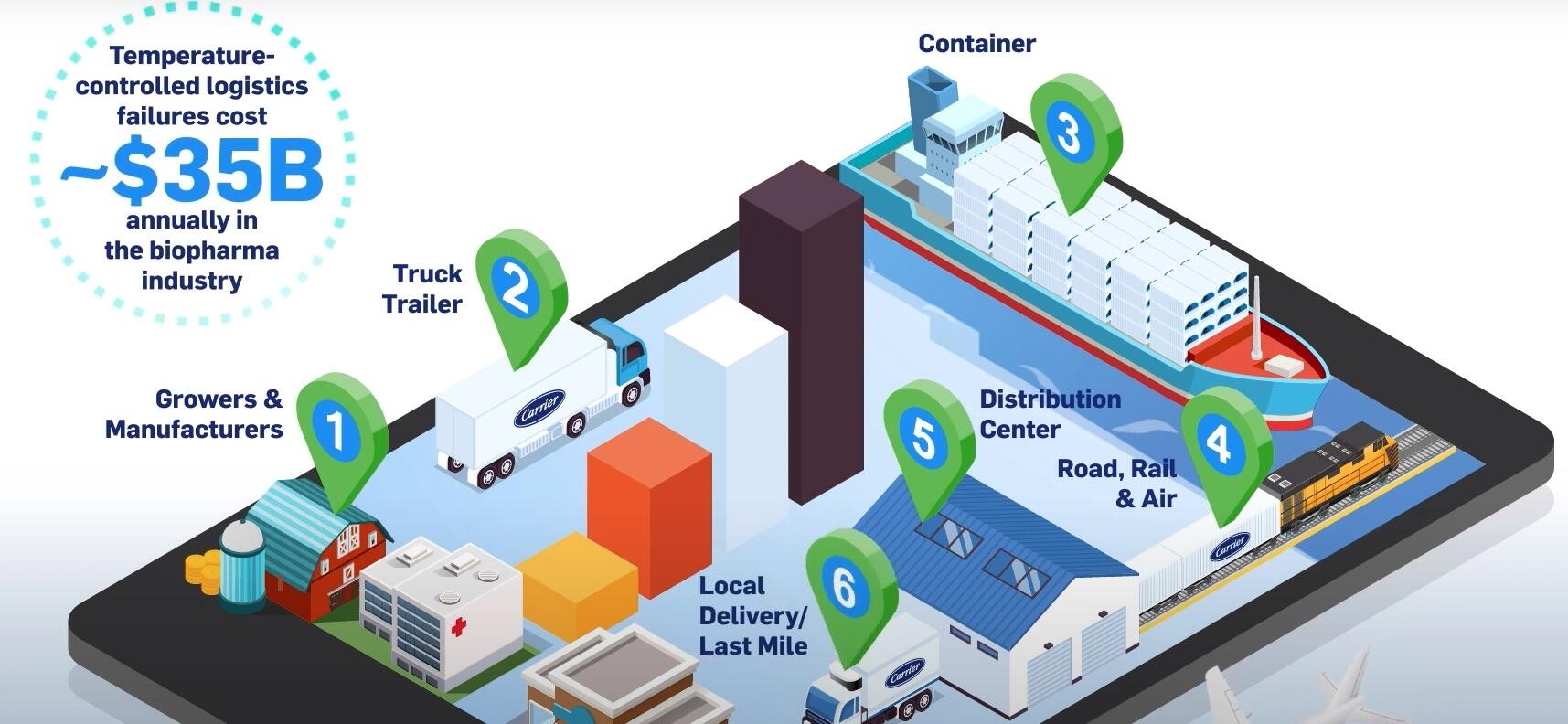

Carrier is working with AWS to improve the cold chain and reduce food waste and spoiled medicine.

Image: Carrier

COVID-19 vaccines have already made a speedy trip from the lab to FDA approval. The next phase—going from pharmaceutical manufacturing plants to the arms of people around the world—is an equally big challenge. This process is getting a digital makeover on the fly thanks to artificial intelligence, automation, and data sharing.

Here’s a look at how tech companies are making the manufacturing and distribution process faster and safer every step of the way.

Manufacturing enough vaccine doses

The world needs billions of COVID-19 vaccination shots as soon as possible. Automation and artificial intelligence (AI) can help with this manufacturing challenge that pharmaceutical companies face.

Peter Zornio, chief technology officer of Emerson’s automation solutions business, said that much of the life sciences industry has been ahead of other manufacturers in adopting digital technologies to optimize manufacturing processes. Pharma and biotech therapeutic companies used this previous experience to fast-track a vaccine.

SEE: TechRepublic Premium editorial calendar: IT policies, checklists, toolkits, and research for download (TechRepublic Premium)

“Automation technologies have played a major role in compressing the timetable from testing to delivery by reducing process setup and production times, shortening batch review from days to hours, automating manual processes, securely integrating disparate systems to ensure data integrity, and providing holistic management of cold chain operations,” he said.

Zornio said the cold chain distribution process is especially critical to detect risks and safeguard critical medicines and vaccines from compound to consumption. He expects the new business processes supported by digital twin platforms and cloud computing to become standard operating procedures when the pandemic ends.

“As we look ahead to 2021 and beyond, pharma companies are well on their way through the digital plant maturity journey,” he said. “Today’s record-breaking digitalized development and manufacturing processes provide more agility, speed to market, and customization that will become the new norm for the development and delivery of life-saving drugs.”

Artificial intelligence also is key to a high-quality manufacturing process. Augury, a Iot company that specializes in tracking the health of machines, works with pharmaceutical customers including Sanofi and AstraZeneca to support research and production. The company’s technology also has been used on machines doing vaccine research.

Saar Yoskovitz, CEO, co-founder of Augury, said that the past eight months have taught us how much of our lives depend on supply chains and the machines that drive them.

“The manufacturing lines for these vaccines are not unique and they are facing the same challenges as any other manufacturer – how do I stretch my machines to the limit and produce at full capacity while having only 50% of my team on site due to lockdowns and distancing regulations,” he said. “This challenge has accelerated the use of digital technologies, like Augury’s, that help leading manufacturers reduce risk and optimize their production.”

Modernizing cold chain distribution

Once the vaccine doses are ready for delivery, public health officials face the next challenge: The logistical work of getting the vaccine to people around the world. According to health data company IQVIA, pharmaceutical companies lose about $35 billion per year in spoiled medications. The two COVID-19 vaccines currently approved for use in the US both require the shots to be stored at cold temperatures.

At AWS re:invent in early December, Carrier CEO Dave Gitlin announced that his company is working with Amazon to give cold chain logistics a makeover. The goal is to reduce food waste and to get COVID-19 vaccines delivered successfully at a massive scale. Carrier’s Lynx platform uses several services from Amazon Web Services to track products from the manufacturing plant through distribution channels to vaccination clinics. Lynx uses machine learning, IoT, and analytics capabilities from AWS to improve:

- Logistics performance

- Diagnostics and prognostics

- Fleet optimization

- Operations cost optimization

“Where data was siloed, we’ll be able to aggregate it,” Gitlin said. “We’ll also be able to spot problems like truck doors being left open for more than 30 minutes.”

He said that logistics experts will be able to combine weather and traffic data to determine when a truck needs to be rerouted to stay on schedule or avoid delays that could cause products to get too warm.

AWS CEO Andy Jassy said at the event that this improved tracking will help to reduce food spoilage as well.

Companies also are using RFID tags to track the position and condition of individual vials of COVID-19 vaccinations. Global life science company MilliporeSigma has a platform that combines RFID labels, a mobile app, and a secure web interface to track open and expiration dates. The company claims that this digitized inventory management system can save time and decrease human errors in the process of storage and handling as well as improving regulatory compliance and documentation.

Powercast produces wirelessly powered sensor tags, which can read humidity, light, and monitor temperature during the entire supply chain to ensure temperature integrity. The Powercast tags allow long range, high-function RFID without a battery.

Delivering injections and tracking doses

National and state healthcare organizations estimate that they need $8 billion to deliver the COVID-19 vaccine to all Americans. This includes hiring staff, producing educational materials, building cold storage facilities, and improving data collection processes. The National Association of County and City Health Officials and the Association of State and Territorial Health Officials told Congress that they need $500 million for data system upgrades.

Microsoft Consulting Services has worked on 230 COVID-19 response projects since the start of the pandemic in March 2020. The company just announced the Vaccine Registration and Administration Solution. The two vaccines approved for emergency use in the US require two doses. This new platform supports this massive distribution effort through secure data exchange that uses Health Level Seven (HL7), FastHealthcare Interoperability Resources (FHIR), and open APIs. According to a blog post, “Health providers and pharmacies can monitor and report on the effectiveness of specific vaccine batches, and health administrators can easily summarize the achievement of vaccine deployment goals in large population groups.”

Tech companies also are helping with the data entry component of the vaccine distribution. A Columbus company is using computer vision and robotic process automation to complete repetitive administrative tasks in hospitals. The company recently has switched its focus from billing to COVID-19 treatment. According to a company spokesman, Olive’s tools have supported COVID-19 testing operations by automating hours of manual data entry and expanding testing capacity. Tufts Medical Center in Boston uses Olive to automate high-volume data entry and patient screening tasks. The technology makes the in-person testing process up to seven and a half times faster and reduces enough manual data entry to lower testing time by 86%, according to the company.

The next phase of the work is tracking which frontline workers receive the vaccine and when. The company expects its digital assistant to reduce deployment time, monitor for side effects and provide data to regulators. Lori Jones, president, provider market, and chief revenue officer at Olive, said that the administrative burden of rolling out the vaccine is significant.

“Employees, and many times direct caregivers, are being tasked with everything from registration activities, to tracking initial inoculation dates, to reminding employees when to receive their second doses within the optimal window,” she said. “AI has an important role to play in ensuring this first wave of doses is administered as efficiently as possible without placing an undue burden on human employees as they juggle other mission-critical tasks.”