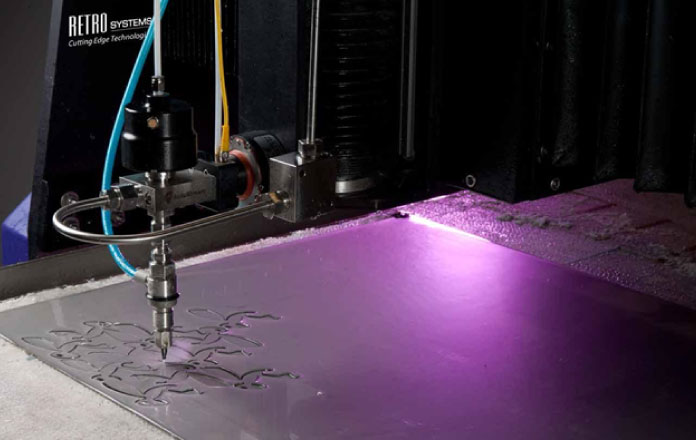

Water jet cutting has completely changed the way manufacturing industries used to work in the past. Traditional cutting methods took a lot of time for processing, thus slowing down the process of manufacturing. As the demand is increasing globally, new technology is finding its way to cater to the needs of different industries. Water jet cutting is one of the newest technologies to work with a variety of materials such as metal, wood, plastic, and whatnot. It may come as a surprise but water has a destructive force that can cut through the thickest and hardest of materials, and this is why numerous industries are benefiting from water jet cutting;

Aerospace Industry

One of the most significant uses of water jet cutting technology is done by the aerospace and aviation industry, responsible for boosting globalization and the movement of goods and people around the world with ease. There’s no denying the fact that there’s no compromise on precision when it comes to the aerospace industry. The smallest of errors or mistakes are responsible for the biggest tragedies. It’s extremely complex to produce parts for such industries but water jet-cutting technology is capable of doing it.

Water jet cutting does not only help in the manufacturing of the engine parts but the whole aircraft itself. Not only this, many military solutions and scientific developments are done with the help of this technology. As there is no thermal distortion when using water jet cutting, it makes this process more reliable. One of the most tremendously performing are Techni waterjet machines which can deal with the complexity of the aerospace and aviation industry.

Automotive Industry

The demand in the automotive industry is increasing rapidly and to cater to that need versatility is essential. Creating parts from complex designs is part of the automotive industry. Water jet cutting machines are capable of cutting interior components as well as exterior components. Almost all aspects of a project can be completed in one place with the help of this technology, not only money but time is saved as well.

When compared to laser cutting technology, water cutting technology provides better finishing and good precision, which is a need in this industry. Smooth finishing is the reason that elegant automobiles are made in such a short period. There’s very less mechanical stress when using this latest technology.

Food Industry

It may come as a surprise but water jet-cutting machines are also used in the food industry. It is used during the processing of food. As it is one of the cleanest ways to cut a material, it’s utilized in the cutting of food. This technology has helped reduce wastage and has fostered productivity at a greater level. Not only this, but it also has high sanitation status which makes it favorable for the food processing industry.

May it be meat, fish, poultry, or frozen food, it can be cut finely through the use of water jet machines. The stream used by these machines is as thin as human hair, making it super precise. Less labor is needed in the industry and more output is produced.

Medical Industry

One of the biggest industries in the world is pharmaceutical and water jet cutting has even made it there as well. The machines are capable of cutting angles up to 60 degrees, making them highly efficient. Not only this, it can hold tight tolerance as well. Laser technology is not suitable for this industry as it can alter the chemical properties of the material, which isn’t an option in this industry. The cold-cutting process of waterjet cutting is tremendous for this industry, as it does not hamper the chemical properties of the material, leading to the better finished part needed in the medical industry.

Defense

It is one of the most sensitive and top-notch industries in the world. There’s no space for the slightest of errors and this is why it relies on water jet-cutting technology for manufacturing military machinery. Water jet cutting machines can work with metals with a thickness of even more than 11 inches. May it be jet engines, rotary blades, and many other parts can be made using this technology.

As this technology does not alter the shape of the material, it is highly demanded in the defense industry. Same as the aerospace industry, the defense also requires high precision which is provided by water jet cutting machines.

Conclusion

Industries globally are making full use of water jet-cutting machines to improve the growth of their business. To produce better quality parts in less time. Moreover, the architecture and design industry is also dependent on the use of this technology as it can cut thick material in irregular shapes as demanded by the manufacturer. May it be interior or exterior architectural designs, it can manage the workload pretty well, providing satisfactory results to the customers.